Basic purpose of a local aspiration in complex with the filter&ventilation aggregates (cartridge filters) and local ventilation aspirators is an elimination of the harmful emissions for the creation of working conditions, which completely meet the requirements of the labor safety and ecology.

Basic purpose of a local aspiration in complex with the filter&ventilation aggregates (cartridge filters) and local ventilation aspirators is an elimination of the harmful emissions for the creation of working conditions, which completely meet the requirements of the labor safety and ecology.

Local aspiration of an abrasive and grinding dust, aerosols at welding operations and soldering, a dust at treatment of solid materials, an oil fog and a coolant provides air purification directly in the place of formation of the harmful substances, thereby considerably reducing power inputs. Formed dust is caught and sent back to the process that prevents utilization of the valuable products.

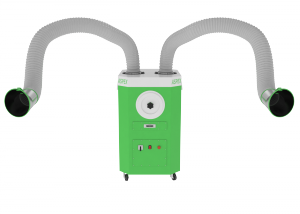

For aspiration of the equipment (welding, crushing, etc.) which can change a zone of the dust or gas emissions, mobile cartridge filters with flexible sampling device of aspirated gas or air are used.

Ventilation at welding

It is necessary to understand, where relatively ‘pure’ and ‘dirty’ areas are formed and properly provide feeding of the fresh air to the pure area, and also carrying out of its removal from the low-purity areas. Therefore, it is possible to say that as a rule in welding shops the largest concentration of the harmful substances contains in the upper zones of a premise and the least one is in the bottom. It is necessary to consider that besides the basic air circulation which is caused by convective streams, in places of intensive welding cold downdraughts occur at exterior walls as well as other factors causing origination of local circulating zones.